After many years of use, the front bottom cutting edge on the bucket of my loader tractor was no longer flat to the ground; the front edge was bowed up almost an inch. I solved this issue by building two ribs from ¼-inch-thick plate steel. First, I formed a nice, straight edge again using two hydraulic jacks to bend the front edge back down. Then, I welded the steel ribs into the bucket.

Ken Miller | Rochelle, Illinois

To get a battery connection for powering up fuel transfer pumps when no electricity is available, I used to have to climb up in the tractor. Now, I keep a solar panel and battery right by each tank, so power is always available. One bonus: I always have a fully charged spare battery.

Doc Zaunbrecher | Crowley, Louisiana

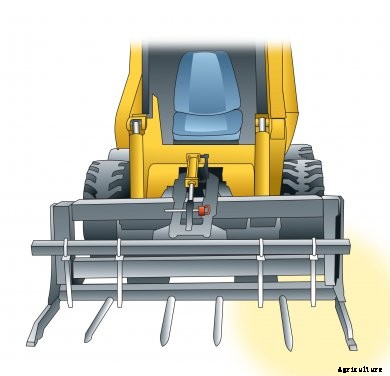

At one time, I would mow road ditches and grassy areas around the farm and leave it instead of trying to rake the hay. Then I built a hay buck for my skid steer. The teeth are made of a PTO shaft from a silage chopper. (The high carbon content makes this steel very strong.) Combining this material with tube steel, I made a grapple. The buck is 5 feet wide. Two loads of loose hay fill a round bale feeder.

Roger Johnson | Chandler, Minnesota

I have a few young employees on my farm who still haven’t memorized the standard/metric wrench size conversions for bolts. Then again, I still have trouble remembering them, too. So for all our sakes, I made a conversion chart and posted it next to the wrench sets. It really helps, especially during breakdowns.

Jonas Waldner | Mitchell, South Dakota

I remodeled an old hand truck by turning the wheels 90°. The original purpose was to move new windows around a house, but I soon discovered its many uses on the farm. I can move heavy objects like a piece of plywood, a toolbox, or a long piece of steel through doors by myself. Nonskid rubber is attached to the face of it so it grips whatever I’m hauling.

Ken Miller | Rochelle, Illinois