Proper calibration of application equipment can be one of the trickiest tasks that homeowners and commercial applicators face. However, it is one of the most important steps in making fertilizer or chemical applications, second only to reading and following the label. An improperly calibrated spreader will apply too much or too little product and may result in uneven fertilization, injury to the lawn or other plants, inadequate control of target pests, environmental harm, and/or a waste of money.

Spreaders should be calibrated for each user. Differences in the height and stride of users create varying walking speeds that can cause differences in the rate of application. As walking speed increases, the rate of application decreases. Inversely, as walking speed decreases, the rate of application increases. When using rotary spreaders, faster walking speeds can cause materials to be broadcast further out from the spreader than at slower speeds. Due to user variability, some landscape companies assign spreaders to specific users to reduce application errors.

Spreaders should also be calibrated for each material applied as each product varies in size, weight, and density. When broadcast at the same walking speed, larger and heavier materials tend to be broadcast further from the spreader than smaller and lighter materials.

A drop spreader (left) and rotary spreader (right).

Cory Tanner, ©2018, Clemson University

Spreaders are used to apply dry granular materials, such as fertilizer, pesticides, lime, or seed. There are two types of spreaders: rotary spreaders and drop spreaders. Rotary spreaders distribute material in a swath much wider than the width of the spreader. These are useful when applying materials to large areas. Drop spreaders distribute materials in a swath equal to the width of the spreader. Drop spreaders are useful when applying materials to smaller areas or around edges (i.e., applying fertilizer around a pool or other sensitive areas).

The procedure outlined below serves as a guide to calibrating rotary and drop spreaders.

Materials necessary for calibrating a spreader.

Justin Ballew, ©2018, Clemson University

Rotary spreaders broadcast material by centrifugal force in a swath wider than the spreader width; however, the swath is not uniform. Material is broadcast heaviest directly in front of the spreader and gets progressively lighter as the distance from the spreader increases. Determining the effective swath width helps applicators properly space their passes to maintain an appropriate amount of overlap. Use the procedure below to determine the effective swath width.

Pans labeled 0-9 placed in a straight line. A space is left between the “0” and “2” pans for the spreader wheel to pass through.

Justin Ballew, ©2018, Clemson University

The material caught in each pan was poured into a cylinder for visual measurement.

Justin Ballew, ©2018, Clemson University

Pan 4 contained roughly half of the material of pan 0.

Justin Ballew, ©2018, Clemson University

Effective swath width indicates how far to space each spreader pass. Therefore, if the spreader has an effective swath width of 8 feet, each pass should be spaced 8 feet apart. Wire flags can be used to help mark the passes.

Make a test strip either in an area of turf that is not being used or on pavement where the material can be swept up and collected. Measure a straight line 50 or 100 ft long and mark the ends with flags if on turf or chalk if on pavement. A distance of 100 ft will be easier to calculate later, though if there is not enough space available, make a 50 ft test strip and walk it twice (down and back) to equal 100 ft.

Determine how much product to apply. The following examples will demonstrate a couple of potential scenarios.

Example 1: A soil test report states that a lawn needs 20 lbs. of lime per 1000 ft2.

Calculate the amount of lime needed to apply to the test strip to deliver 20 lbs. per 1000 ft2. Assume the effective swath width of the spreader is 6 feet, and the test strip is 50 feet long.

Lime per 1000 ft2 x (swath width x length of test strip) ÷ 1000 ft2 = lime needed in test strip

20 x (6 x 50) ÷ 1000 ft2 = 6 lbs of lime needed in test strip

Example 2: A soil test report states that a lawn needs 1.0 lb of nitrogen (N) per 1000 ft2. The purchased fertilizer has an analysis of 10-10-10. Two coverage passes will be made, so 0.5 lb of N per 1000 ft2 will be applied on each pass.

1. Calculate the amount of fertilizer needed to apply 0.5 lb of N per 1000 ft2. The fertilizer to be used contains 10% N (in decimal form this would be 0.1).

0.5 lbs N per 1000 ft2 ÷ 10% N fertilizer = X lbs of fertilizer per 1000 ft2

0.5 ÷ 0.1 = 5 lbs of fertilizer per 1000 ft2

2. Calculate the amount of fertilizer needed to apply to the test strip in order to deliver 5 lb of fertilizer per 1000 ft2. Assume the effective swath width of the spreader is 8 feet, and the test strip is 100 feet long.

Fertilizer per 1000 ft2 x (swath width x length of test strip) ÷ 1000 ft2 = fertilizer needed in test strip

5 x (8 x 100) ÷ 1000 ft2 = 4 lbs of fertilizer needed in test strip

Once the rate has been calculated, use the test strip to adjust the spreader.

The spreader adjustment is set to the middle setting.

Cory Tanner, ©2018, Clemson University

This scale has been tared for the weight of the bucket and now reads “0”.

Cory Tanner, ©2018, Clemson University

The material left in the spreader after walking the test strip is poured out to be weighed.

Cory Tanner, ©2018, Clemson University

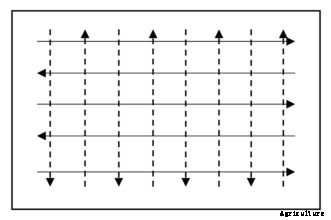

Two coverage passes ensure good coverage. The hashed lines represent a coverage pass in one direction and the solid lines represent the second pass perpendicular to the first.

Justin Ballew, ©2018, Clemson University

Sample Problem:

A soil test report states a lawn needs _____20______ lbs of lime per 1000 ft2.

The effective swath width of the spreader is ___6___ feet and the test strip is ____50____ feet long.

Calculate the amount of lime needed to apply to the test strip using the following formula:

Lime needed per 1000 ft2 x (swath width x length of test strip) ÷ 1000 ft2 = Lime needed in test strip

____20____ x (___6____ x ____50_____) ÷ 1000 ft2 = ______6______lbs

lbs of lime per 1000 ft2 swath width (ft) length of test strip (ft) lime needed in test strip

Applicator’s Info:

A soil test report states a lawn needs _____________ lbs of lime per 1000 ft2.

The effective swath width of the spreader is _______ feet and the test strip is __________ feet long.

Calculate the amount of lime needed to apply to the test strip using the following formula:

Lime needed per 1000 ft2 x (swath width x length of test strip) ÷ 1000 ft2 = Lime needed in test strip

__________ x (________ x ___________) ÷ 1000 ft2 = _____________lbs

lbs of lime per 1000 ft2 swath width (ft) length of test strip (ft) lime needed in test strip

Sample Problem:

A soil test report states a lawn needs__0.5___ lbs of nitrogen (N) per 1000 ft2.

We’ve purchased a fertilizer to apply which contains __10__% nitrogen.

The effective swath width of the spreader is ___8___ feet and the test strip is ____100___ feet long.

______0.5_______ ÷ ______10_______ x 100 = ______5___________lbs

amount of N needed (lbs) % N of the fertilizer fertilizer needed per 1000 ft2

______5_____ x (___8___ x ____100____) ÷ 1000 ft2 = _____4______lbs

fertilizer per 1000 ft2 (lbs) swath width (ft) length of test strip (ft) fertilizer needed in test strip

Applicator’s Info:

A soil test report states A lawn needs ________ lbs of nitrogen (N) per 1000 ft2.

We’ve purchased a fertilizer to apply which contains ______% nitrogen.

The effective swath width of the spreader is _______ feet and the test strip is __________ feet long.

________________ ÷ _______________ x 100 = __________________lbs

amount of N needed (lbs) % N of the fertilizer fertilizer needed per 1000 ft2

____________ x (________ x ___________) ÷ 1000 ft2 = ___________lbs

fertilizer per 1000 ft2 (lbs) swath width (ft) length of test strip (ft) fertilizer needed in test strip