Kyle Plattner has spent his career at the intersection of technology and agriculture. He’s had a foot in both worlds nearly all his life. Plattner earned a computer science degree from Eureka College and a master's of information systems from Robert Morris University. He spent nine years working for Precision Planting and The Climate Corporation on the FieldView cab team. Since 2019, he’s been using that passion to improve John Deere’s Operations Center mobile app as the senior product manager.

At the beginning of 2021, he sat down with Successful Farming for an exclusive interview as part of the virtual Consumer Electronics Show.

A: I love the intersection of ag and technology. Both my grandparents farmed, so I had that on both sides. Yet, growing up, I watched my dad work at IBM. I’ve always felt comfortable in this space.

My undergrad was computer science and following graduation in 2010, I started with Precision Planting. During that time, Monsanto acquired Precision Planting. Our team was moved into the Climate Corporation where I was up until summer of 2019 when I joined the John Deere team.

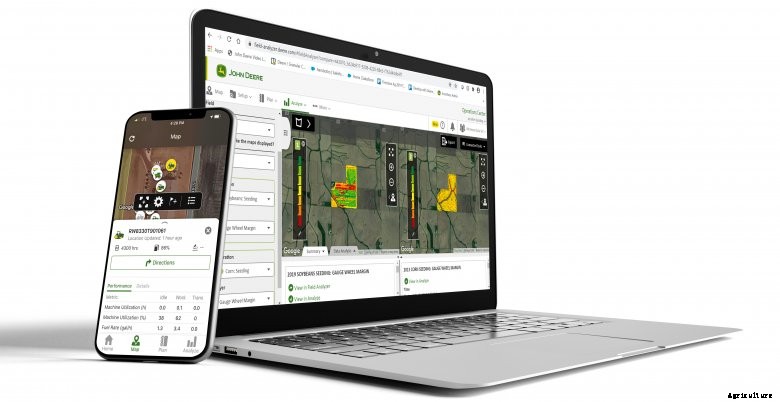

A: Operations Center is our set of tools that enable you to set up your equipment to make sure that it’s ready to go in the field and collect good data to plan out what you’re going to be doing on your farm, so that when you get to the field everything’s ready to go.

It helps farmers monitor, which is a space I have particular interest in: the ability to see and keep a pulse on what is happening out on the farm as it’s happening. We’re uploading data from our equipment in real time and allowing any farm manager to have visibility into that as work is happening.

Lastly, it gives analysis tools. With all this data that we’re collecting and have been collecting for a long time, we can begin to extract some value out of it and use it in day-to-day decision-making. Things like, what equipment I should buy next, or what products or varieties worked on my farm? These are the type of things Operations Center is really poised to solve for our customer.

A: We’ve seen a dramatic increase in the use, particularly of our mobile tools. One great example is we have a service that we call Remote Display Access. Remote Display Access allows anybody on the farm, or a dealer, or an agronomist – anyone like that, it enables them to basically log into the display in the cab and see exactly what the operator is seeing.

The situation might be that an operator is out in the field and encounters some sort of trouble. Somebody who can support that person doesn’t have to go to the cab so that they can see what’s going on in the display. Instead, they can pull it up on their phone and walk through different diagnostic information to get a sense of what is happening and support that customer from a thousand miles away.

As we’ve watched the usage of Remote Display Access, we’ve seen substantial increase – off-the-charts, hockey-stick growth during this time.

A: I’m not in a position to share exact numbers at this point. It is dramatic. I would say this is a 2× to 3× increase over what we had last year.

A: I would say we have really invested deeply into our monitoring capabilities so that from wherever they are, people can take advantage of being able to understand what is going on on the farm and support operators as they are out in the field. Because of a shift in interest, we have to make a shift in investment to correspond to that.

We feel like these tools are playing a much more vital role on the farm than they had previously. We’re going to continue to innovate to meet our customer needs in that area.

A: I think a lot of things won’t return to the way they were. Once you begin to rely on digital tools, it’s hard to go back. On planting day, for example, I want to make sure the right variety is being planted at the right rate. Where I may have made a phone call or texted before, now that I have it available on my phone, it’s way more convenient. Once I’ve embraced that and adopted it on my farm, going back to sending a bunch of texts or making a phone call, with the efficiency loss, it would be hard to go back.

I think there will be a steady continual embrace of these technologies just like there has been. They won’t just return back to the way things were. This has accelerated the trends that we were already seeing.

A: We’re all mourning the loss of the free hats, and we’ve consumed a lot less free coffee in Styrofoam cups. Such is the nature of 2020.

It has been more challenging to have a direct line of communication with our customers. That’s something we take seriously – our ability to keep an ear out for our customers’ needs. Historically, that looked like doing a lot of farm visits, and all of a sudden we can’t do that anymore. Not like we used to.

We’ve tried to really embrace this technology to be able to video chat with customers. We’ve had a surprising number of people willing to do that. I think people are eager to share about their operations, and if they have to do that in a nontraditional format, they’re very willing to do that, especially if they can share feedback that really directs and guides our product development process. And it really does. We really change what we’re working on, what we’re investing in, what we’re focusing on based on what we hear from our customers.

We’ve made a tremendous shift from farm visits to Zoom visits over the course of the last year. I think it’s still proven to be effective and still proven to be something that we get a lot of value out of.

A: In a traditional farming setup, you may have an operator who is less skilled and is running the planter or sprayer, but isn’t the manager. A lot of times when you’re getting that person up and going, you’re there to make sure everything is up and entered the way it’s supposed to be.

What we’ve done with some of our planning tools is enable a farm manager to do all of that input and validation of the right product at the right rate ahead of time, before they get to the field. They can just send it down to the equipment. Now, because of the pandemic where they’re not going to go out to the field and be in the cab with the operator on planting day, they can have an assurance and a confidence that the details they had intended are actually being executed in the monitor without being there in person.

That’s one example of how we’ve needed to adapt workflows and emphasize different parts of our system in order to align with the needs of our customers in this changing landscape.

A: I think the value of these tools is one of those things, as time moves forward, that’s getting easier and easier to demonstrate. I think they will become so compelling and have such an essential role on the farm that you couldn’t farm without them.

Think about precision guidance with GPS. If you go back three decades ago, it’s not really a thing. Fast forward another decade, and another decade. All of a sudden it’s to the point now, if your precision guidance system goes down, you’re down. That’s a flat-tire event almost. Not that you couldn’t continue without it, but in most cases, you’re going to stop and get that thing fixed before you move on. There’s a technology where reliance on it grew to such a point that no one would even consider farming without it.

I think we’re seeing the same trend with digital tools. It’s getting to a point where I can’t farm without having visibility into my entire fleet and knowing exactly where they are, what’s going on, and how to dispatch them to the next place. It becomes really essential.

A: We need to double down and make our tools really simple to use when something goes wrong, simple to troubleshoot and understand the problems. When it becomes an issue larger than a farmer can fix, we need to have really great support.

That’s one thing we can say at John Deere: You’re never far from a dealer who is able to come out, look at your situation, and address your specific problem. I don’t think you’ll find a dealer support system that is as strong and robust as ours is. We will continue to leverage them, as we have historically.

A: As we think about how we’re working as a team, we’ve gone from working in a small office with the people I collaborate with every day. All of a sudden, we’re all remote and it has made us figure out how to work stronger as a non colocated team. It’s really upped our game in terms of figuring out how to communicate over video chat or messaging. I think in general, it has made us a more resilient team. It took effort, and was something we needed to learn. It was a new muscle that needed to be exercised when the pandemic hit.

A: I’m most excited right now about some of the new monitoring capabilities that are coming this year. The ability for a farm manager who has a full fleet to be able to see up-to-the-minute where every piece of equipment is, what it’s doing, and if there are any problems with it that they need to pay attention to. These are tools that equip a farm manager to keep a pulse on everything that’s going on across an entire organization, no matter how many people or machines or acres, and pretty effortlessly from a device in their pocket. I think that’s huge, and I can’t wait to see how farmers use these capabilities over the course of the year.

A: It’s definitely something that we want to accommodate. We support upload data from all major third-party systems. If you do own a non-Deere display, you can pull the data right off that and bring it in. Or in some cases, we have API agreements with other platforms and are able to suck that data in automatically. In other cases, you’re uploading it, but either way, we really want operations center to be a full farm solution. We’re seeking to make it as broadly applicable as we possibly can.

A: If I farm alone, I want somewhere I can get all of my data in one place that is trustworthy, where I don’t have to worry about data security. We have a cloud storage solution. On top of that we have really powerful analysis tools to help them slice and dice and understand their data and extract some insights and value from it. Regardless of your farm size, Operations Center is a great solution for that.

As a side note, we spend a lot of time, effort, and energy making sure our data is secure and making sure that only you have access. Only the people you’ve given permission to have access. That’s something we take a lot of pride in. We have a data privacy policy that is in plain English.

A: It means a faster adoption of some of the hardware that makes our full solution more powerful. An example would be growers who might have older 2630 displays still in their cabs updating to a Gen 4 display, buying some of the premium activations, equipping all of their equipment with 4G MTG units that are able to have broad connectivity across their entire fleet. When growers are in a position to spend some more on their operation, they’re going to embrace some of these technologies a lot faster than they would otherwise.

A: Rural connectivity is huge for us because we have equipment that goes everywhere, equipment that goes in areas where connectivity isn’t great. That’s one of the reasons why Deere has been a huge proponent and advocate for extending the availability of cellular connectivity in rural areas. I would say that we will continue to do everything we can to advocate for that.

It’s really huge because we have two-way communication with the cloud from our equipment. From the cab to the cloud, we’re receiving things like plans or setup files, or instructions that the operator needs. It’s also uploading the data that it is collecting in the field, so that it is available both for monitoring and, after the work is done, all the analysis data is there in the cloud.

We absolutely depend heavily on connectivity and that’s why we’re so interested in seeking out its broad availability.

A: I would say that agriculture is strong, as an industry. There are a lot of other industries that have fears about what the future means for them. How strong are certain sectors of our economy going to be? Here’s the truth. We know that for as long as people continue to eat food, and wear clothes, agriculture is essential. So have hope, have faith that no matter what, agriculture is going to continue to grow. That’s why we’re so excited to be serving this industry with the best-in-class tools to keep farmers doing what they do best, which is providing food and fiber for us all.