Hydroponic Fodder for Dairy, Goats, Poultry, Livestock – A Complete Guide

Today, let us discuss Hydroponic Fodder For Dairy, Goats/Sheep, Poultry/Chicken, and other Livestock including Hydroponic fodder system cost.

Green fodder is the natural diet for livestock. The production of green fodder to meet the current demand has become a big challenge among livestock farmers. Due to many reasons, green fodder production has been facing a crisis and so livestock productivity. The main reason can be the intensive system of rearing livestock, which needs huge quantities of green fodder. As the gap between the demand and supply of the green fodder for livestock becoming unconquerable, researchers and farmers are in search for an alternative fodder or fodder production method, that would restore fodder and livestock production.

The solution can be Hydroponics, a technology that has revolutionized the green fodder production in the 21st century. Hydroponics is the latest technology of growing green fodder without soil in an ecological environment. Many livestock farmers are influenced by this method and are switching to hydroponic fodder production from conventional production methods, as the fodder produced by this method are highly nutritious, through this process you can produce fodder around the year and conserve water.

Though this method has made a greater impact on the fodder production system, many of the farmers are facing some obstacles in running the hydroponic machine efficiently for sustainable fodder production.

Now let’s get into a detailed discussion:

What is Hydroponic?

The word hydroponics is originated from the Greek word ‘water working’. The word Hydro means ‘water’ and the word ponic means ‘working’ and the whole word means, it is a method of growing plants in water or nutrient-rich solution without soil, for a short duration in an environmentally controlled house or machine.

What is fodder?

The word “Fodder” means a food given to the animals (fodder can be plants cut and carried to them), rather than that which they forage for themselves in pasture and grazing land. It also includes hay, straw, silage, compressed and pelleted feeds, oils and mixed rations, and sprouted grains and legumes.

What is hydroponic fodder?

Fodder is grown using hydroponics technology.

Why Hydroponic green fodder?

- Saves water Consumes 98% less water than conventional methods and the used water is recycled.

- Reduced growth time Takes only 8 days duration to develop from seed to fodder while it took 45 days for a conventional fodder to grow. Enhanced nutritive value – as the fodder contains the seed along with the fodder, it has higher crude protein content than conventional green fodder.

- Marginal land usage Up to 1000 kg green fodder can be produced from 480 square feet area daily which is equivalent to conventional fodder (Co4) produced on 25 acres of cultivable land. Use 99% less land than a conventional production method.

- Constant supply Fodder can be produced around the year, irrespective of the failure of monsoon, land availability, natural calamities, a labor shortage. Promotes sustainable agriculture and livestock production. Requires minimal manpower and time

- Only 2 -3 hours of work daily, doesn’t involve technical work.

- The Farmer can do the work without difficulty.

- Completely natural and organic. Fodder is grown completely naturally without the use of any pesticides.

- Reduce feed cost As the fodder contains more crude protein than conventional fodder it reduces the feed cost spent on the concentrate feed to half.

- Minimal equipment usage Reduce the need for equipment and fuel used to plant, grow, harvest, transport, and store feed. Nutritious fodder Hydroponic fodder along with seed and root (sprout mat) are highly edible and are rich in protein (10 – 17%). Ideal nutrients enriched fodder for livestock.

Read: RAS Fish Farming Equipment, Cost, Training.

Do the livestock really like it?

The answer is ‘yes’. Palatability of hydroponic green fodder was excellent among farm animals as it is succulent and delicious.

What can be grown as a Hydroponic fodder?

Yellow Maize, Cowpea, Horse gram, Sun hemp, Ragi, Bajra, Foxtail millet, and Jowar have been grown successfully and received good response from the livestock as a fodder.

What are the major requirements for hydroponic fodder production?

- 480 square foot area for production of 1000 kg of green fodder daily. Production capacity depends on house capacity.

- Hydroponic machine.

- Uninterrupted power supply.

- Clean water.

- Seeds with good germination capacity.

- Good sanitation.

- Two to three labors for continuing observation.

How to construct a Hydroponic Fodder System?

Hydroponic System details-

Hydroponics fodder unit is nothing but a chamber with the arrangement of temperature, humidity and light intensity for maximum sprouting & growth of fodder crop seeds (mainly maize, oat, barley, wheat etc). With 30 to 35˚C temperature, 60 to 75% humidity and 50 % shed 1 Kg of maize should yield 6 to 8 Kg green fodder in 7 to 9 days. It found that for 6-8 times mass increase around 2 lit water is enough per kg of seeds during the summer season. So with this one can grow very well, healthy & economical viable fodder for dairy/goat farming.

There are plenty of manufacturer suppliers of hydroponics systems in the market, but farmers can build their own system as it is very easy to fabricate & all components available in the market. The Following are required components with their specifications-

System components-

Growing cabinet, Racks for trays, trays, seeds, watering system (Fogger/Mister/drip pipes), timer, and motor.

Growing cabinet-

Square shape cabinet is most suitable & easy to fabricate, cabinet size can vary based on the number of trays, a cabinet can be fabricated with mild steel pipes (MS), UPVC or bamboo. Just make square box and tray arrangement. Slotted angle racks can also serve the purpose. Cabinet needs to be covered with 50 % green shed net and/or polyhouse covering film for reducing light intensity & conserve humidity.

Racks for trays-

Can be of MS, UPVC or bamboo. The height of the tray racks needs to be arranged as per day cycle of fodder i.e. lower level 2 racks with 6 inches, above 2-3 racks on 8 to 12 inches and upper-level racks 12 to 15-inch height. A gentle slope is beneficial for avoiding water lodging and fungal growth.

Trays-

Various kinds of trays are available in the market based on the quality of plastic & durability, specialized hydroponic trays are costly (2 feet * 2 feet tray cost approx. Rs.350). We can use simple office tray (1.5 feet *1 feet) with perforations at the bottom (simply drill holes on equal distance). Make sure there are sufficient holes made to avoid any kind of waterlogging and avoid fungal infection. After every use, the tray needs to be disinfected by diluting hydrogen peroxide and sun drying.

Seeds-

Maize, wheat, oat, barely are ideal for hydroponics. Select based on availability & rate per unit. Seed should be free from any fungal infection. To remove broken seeds, give brine water treatment and remove floating seeds. Soak seed further hours in potassium permanganate. Once seeds spouted, 2 treatments of powder tricodermaSp will also help in lowering fungal infection. A seed rate of 0.5 Kg / Ft2 is sufficient for hydroponics fodder cultivation.

Watering system-

The motor pump of 0.25 or 0.5HP is sufficient for a 100-tray system. For lesser capacity, minimum 0.25 Hp motor will be required for operating fogger/misters.

Drip line-

Regular 16 mm HDEP drip line is best suited.

Timer-

Various timers are available in the market. Timer best suited is generally 1 to 2 min operation every / hour. We prefer Frontier TM-619-H-2 with 17-time intervals. If the motor pump is above 3 Amp additional really is preferable.

During winter months when night temperature reaches below 15˚C, seed sprouting and growth effect, lowering net yield & higher harvesting time. During these months’ addition seed sprouted / incubator may require. This seed sprouted can be fabricated easily by making a small chamber inside the hydroponics chamber with additional temperature increasing facility as filament bulbs, heater, etc.. Proper seed sprouting is very important in hydroponics, for best results, seed can be soaked in lukewarm water (40 to 45˚C) for 8 hours and sprouted at 35 to 38˚C with 90 % humidity.’

Hydroponics Fodder System Construction Process:

- As per your necessity of fodder, design your Hydroponic fodder system. And a hydroponic system occupies very little space, ideal size can be 10 ft x10 ft shade net, and choose the location for hydroponic system near to the livestock.

- This system needs good ventilation, so leave a certain amount of space between the roof and side walls, a shed with good light and air flow will have an optimum temperature and humidity levels.

- Chose medium sized trays, plastic is the best choice than the metal one.

- Inside the shed, build a rack with a bamboo, plastic rack or metal rack to hold the trays.

- Each rack should have three to four layers rack, don’t build to high racks as it is difficult to maintain.

- Give enough space between two layers, and create slightly slope for each layer to one side of the rack for water to drain quickly from the trays.

- Build a small drainage line under the slope side of a rack for proper water draining.

Read: Hydroponic Lettuce Farming.

Steps to Grow Hydroponic Fodder?

Seed storage and preparation

- Dry the seeds under direct sunlight one day prior to seed washing.

- Remove broken seeds and dirt’s from the seeds.

- Store seeds in a dry and safe place.

Seed washing

- Take good quality seeds in a washing chamber.

- Add water.

- Wash the seeds with proper scrubbing by hand.

- Keep for settling for 5 minutes.

- Remove the lightweight floating seeds.

- Drain out the water and again add water.

- Stir manually with a wooden stick for 5 minutes, keep settling for 5 minutes.

- Drain water.

- Repeat the above steps till dirt and dead seeds are removed completely.

Seed cleaning

- Prepare a 0.1% cleaning solution in a plastic tray.

- Add washed seeds to this 0.1% cleaning solution.

- Stir manually with a wooden stick for about 5 minutes.

- Keep for 1 Hour.

- Drain the cleaning solution.

Seed soaking

- Prepare stimulant Solution in the soaking chamber as per quantity is given in the table below.

- Add seeds from the above steps to the soaking chamber.

- Close the lid and keep for soaking for a number of hours.

- After soaking for the given hours, drain the stimulant solution.

Seed germination

- Cover/ place the “After soaking seeds” with the clean dry fumigated gunny bag.

- Keep the seeds loaded gunny bags away from direct sunlight.

- Keep the lid open & keep for germination for a certain period as per fodder you are growing.

- Sprinkle water on gunny bag every 2-3 hours so that the gunny bag remains wet.

- After that, remove the seeds from a gunny bag take the weight.

- About 35 to 40% increase in weight happen with about 90+% seed germination.

Loading seeds in trays and racking

- Ensure that the trays are clean, washed with a cleaning solution& are free from any dust/dirt, etc.

- Transfer “after germination seeds” on the trays equally and put them in the sprout section (the lower section where the height between two rows is around 5 inches) of the machine

- Trays should be distributed evenly on both sides of the alley.

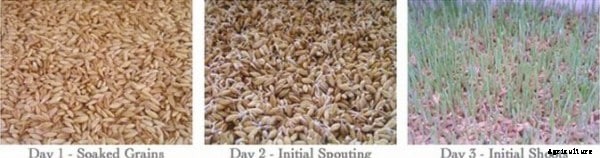

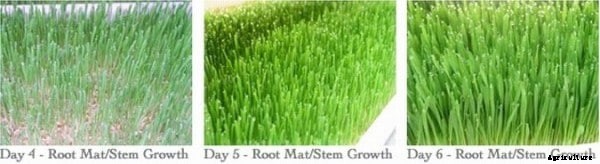

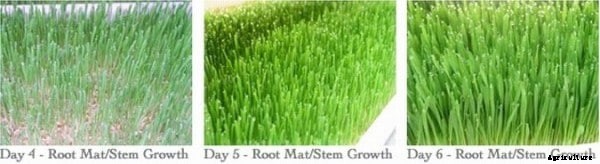

Day 4-6.

Day 4-6.

Shifting of trays

- Shift trays to next level daily so that it moves one step ahead in the growth cycle.

- Take the last tray out of every row and put it back on the front side of the same row.

- Ensure that all trays are moved one position every day

- Ensure that all trays receive enough water.

- If the left side of the tray (in any tray) shows more growth, then the right side (or vice-versa) then rotate the tray such that left side comes to the right side and right side of the tray goes to the left side.

-

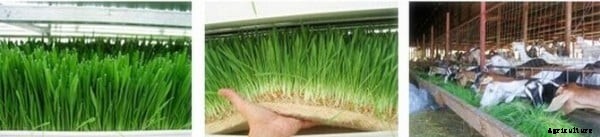

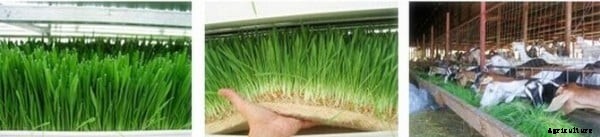

Harvesting (Day 9)

- Trays on the 8th-day rack are ready for harvest on the next day.

- Take out of the fodder mat from trays to feed livestock.

- Wash the trays with clean water and then in cleaning solution before reusing it for the next cycle.

Day 7-8.

Day 7-8.

Read: Hydroponic Farming Training in India.

Steps for Water tank maintenance in Hydroponic Fodder Production:

Water sanitation: provide daily 5% cleaning solution dosing to the external water tank to prevent microbial/algae/fungus growth.

Water tank cleaning:

- Change water in the external water tanks after every 3 days.

- Drain the tank completely.

- Let the tank dry.

- Clean the tank properly.

- Fill with fresh water

Water filter cleaning:

- Clean water filter thrice a day.

- Remove the cleaning lid on the filter.

- Clean the filter.

- Replace the filter.

- Turn on the pump to ensure that filter throws out the water from the opening this way, the filter will also throw out any accumulated dirt along with water.

- Close the lid.

Read: Application, Uses, Benefits of Epsom Salt on Plants.

Hydroponic Fodder equipment maintenance:

Tray cleaning:

- Clean the trays regularly after final fodder removal.

- After removal of final fodder, clean the tray with fresh water

- After cleaning the trays wipe the trays using 0.5% cleaning solution or disinfectants.

Chamber cleaning:

- Clean seed washing and soaking chamber, aluminum stool, gunny bag, etc. regularly after every soaking and germination cycle.

- Clean the equipment with fresh water.

- After cleaning with fresh water, clean using 0.5% cleaning solution or disinfectants.

System maintenance in Hydroponic fodder for dairy:

Machine cleaning in hydroponic fodder for dairy :

- For control of fungus/molds, sterilize the machine regularly twice in a month.

- Switch off the power supply of the machine.

- Remove all trays out of the machine.

- Clean all inner surfaces of the machine, e.g. aluminum pipes, tube light covers, drips, lateral pipe, PVC pipe, etc. use detergent solution and hard brush that can reach to all surfaces to remove any seeds, dirt material, algae or any possible fungus spore that could have grown due to high humidity inside the chamber.

- Use the jet cleaner pump (cold jet pressure pump) for the cleaning (pump pressure should be the minimum 120-130 bar).

- Wipe the inner surfaces using 0.5 % cleaning solution or disinfectant.

- Keep the trays inside the machine &the switch mains power supply.

- If uncontrollable fungal growth noticed fumigation using Formalin (40%) and Potassium permanganate can be done.

Hydroponic fodder for dairy unit area maintenance

- Have a foot bath at the entrance of the unit.

- Fill the foot bath with disinfectants.

- Change the disinfectant daily.

- Follow separate way for the entry and exit of workers.

- Avoid stray animals’ entry into the unit.

- Avoid rodents’ entry into the unit as well as the seed storage room.

- Keep the area clean.

- Avoid frequent entry of visitors into the unit and the working area.

Hygienic measures in Hydroponic Fodder for Dairy unit:

- Personnel hygienic measures should be followed by the persons working in and around the machine.

- Follow separate ways for the entry of seed into the machine (seed inlet) and exit of full-grown fodder out of the machine (fodder outlet).

- It is advisable to wear clean clothes, apron, caps and rubber gloves, and separate chapels while carrying out work in the hydroponic machine.

- Disinfect the apron, rubber gloves and chapels with disinfectant solutions before starting the work and entering into the machine.

- Do not use the same gloves for shifting trays that have been used for loading seeds as seeds may contain some fungal spores that would spoil the fodder production.

- Do not enter into the seed storage room before working necessary.

- Only one person is advised to work inside the machine to minimize the microbial load.

- Another person from outside the machine should assist the worker inside the machine in removing the grown fodder and in sifting the trays.

Major Problems in Hydroponic Fodder for Dairy:

Poor germination:

In the case of poor germination, check with following causes.

- Check the seed quality.

- Buy the seeds from farmers rather than seed shops.

- Buy seeds with less waste and unbroken tips.

- Do not buy seeds stored for a prolonged duration.

- Check the moisture content of the seed (seed should have less than 12% moisture).

- Check the water quality.

- Do not overload the trays with a high quantity of seeds.

- Avoid fluctuation of electric current.

Fungal attack:

In the case of fungal attack:

- Check the fungi (Afflatoxin) level in the seeds. 1 ton of grain comes with 100 billion mold spores

- Check the sprouted seeds for fungal growth. Do not sprout the seeds in an airtight closed chamber. Sprouts and mold grow in a warm and wet environment.

- Check the machine fungal growth.

- Check for leakage of rainwater into the machine.

- Check the recycling water in the tank.

- Clean the water tank periodically.

- Clean the machine twice a month.

- Clean the sprinklers.

Follow hygienic measures:

- Check for waterlogging inside the machine.

- Check the water draining holes for any block.

- Check for clogging of sprinklers.

Bleaching of leaves:

- Check the chlorine level in the water.

- Reduce chlorine level used for sanitation of water.

Drying of leaves:

Check for the fluctuation in the cooling system and the condition of AC.

Pouring of water over plants:

Check the pipelines and sprinklers for clogging.

Stagnation of water inside the machine:

Check the filters for clogging.

Poor water quality in the storage tank:

- Check the status of UV light.

- Check the water filters.

Hydroponics Fodder Machine specification

The hydroponic machine consists of

- A growing chamber which consists of sprout section where the height between two rows is around 5 inches (day 1 to 4) and the growth section where the height between two rows is around 13 inches (day 5 to 8).

- Automated control system –Environment control system.

- Air cooling unit – Air conditioning unit with air blowers.

- Water recycling unit – UV light, filters, and ozone.

Special features

- Daily electricity consumption – 35 -40 units.

- Water drainage in less than 3 minutes.

- Artificial light control for photosynthesis.

- Water sterilization control.

- Water flow control.

- Water recycling system.

- Uniform air circulation through multiple circulatory fans.

Hydroponic Fodder Machine Cost in India:

The cost of hydroponic fodder machine cost depends on the number of trays or capacity of fodder production. Usually, on average, a 50 tray hydroponic machine may cost Rs. 50,000 to 60,000. It may go up to 1,50,000 depending on the growing area. If you are serious about establishing a hydroponic fodder for dairy, you can inquire for the hydroponic setup cost.

The conclusion of Hydroponic Fodder for Dairy:

The fodder produced from hydroponics system can be used as Hydroponic fodder for Chicken/Poultry, Hydroponic fodder for Goats/Sheep, Hydroponic fodder for Cattle/Dairy, Hydroponic fodder for Pigs, and other livestock. The feeding quantity of hydroponic fodder depends on animal age.

Read: Spirulina Farming, Cultivation Practices.